Pouch Resources

Need Help? We're Here For You.

Talk To A Real Person Who's A Real Expert.

Get live support from our LiveChat or get us on the phone.

You can download templates for both stand up pouches and flat pouches by clicking these links. If you need help understanding how a file is properly set up, check out this test file. You can always reach out to us with questions or read below for instructions.

Stand Up Pouch Templates

- 3.25" x 4.75" x 2" Stand Up Pouch Template

- 4.375" x 6" x 2" Stand Up Pouch Template

- 5" x 6.5" x 2.5" Stand Up Pouch Template

- 5" x 7" x 3" Stand Up Pouch Template

- 5.75" x 7.5" x 2.5" Stand Up Pouch Template

- 6.5" x 8" x 2.5" Stand Up Pouch Template

- 6.75" x 8.5" x 3.5" Stand Up Pouch Template

- 7" x 9" x 3" Stand Up Pouch Template

- 7.25" x 6" x 2" Stand Up Pouch Template

- 8.125" x 10" x 3.5" Stand Up Pouch Template

- 9.875" x 10.5" x 3" Stand Up Pouch Template

- 12" x 12.5" x 3.5" Stand Up Pouch Template

Download our pouch material data sheets below. Each sheet provides key details on barrier properties (resistance to moisture and oxygen), film thickness, FDA compliance, and more. If you need guidance on a specific material or film option, our packaging specialists are here to help!

What type of graphics files do I need to submit?

We require that any artwork and graphics are supplied as a high-resolution Adobe PDF files. Important Note: Please ensure your art work is a layered file built in CMYK. (Not RGB or a flattened PSD file). Creating your art in Adobe Illustrator is preferred to ensure efficient pre-press time/proofing. If you're looking to target a specific spot PMS color, ask a packaging specialist about our CMYK+ extend gamut printing.

What guidelines should I use for designing my pouch?

We have templates listed above. Submit files as layered PDFs. Build art in Illustrator with template on its own layer > export as a PDF > submit file online.

Final Trim

Is the finished bag size. Place artwork on a separate layer and please include bleed (if applicable). Avoid placing text in Seal and Zipper areas, also hang hole (if applicable). Take into consideration any art above the tear notch.

Fonts

Outline or send all fonts used in the file. There are often multiple versions of common font names, and they are not exactly alike. Please outline all fonts or include them with your art. Replacing fonts can create slight variations in spacing and may have different special characters. If you outline the fonts we cannot make any changes to the type.

Adding a Window / White Ink Layer

White ink is printed behind your art to give colors strong opacity. If you're looking to create a window on your pouch, or a spot metalized effect, you will need to indicate those areas in your art file. Please create a separate layer in the file for white ink to be used for printing. This will help save considerable time and will show exactly where the white ink is to print and where it is not. Check out our white layer resource sheet for more instructions.

Images

Raster images must be 300 dpi or larger. Vector images are made up of scalable objects, whereas raster images are made up of pixels. A vector image is generated by an algorithm that permits the image to scale up or down with no loss of image quality. This is the preferred format for text and line art (Adobe Illustrator®). A rasterized image is a pixel-based image in which the resolution is predetermined at the beginning of the build process. Photographic images are usually raster-based. Once the resolution is established for a raster image, adjustments to a higher resolution will degrade the image quality (Adobe Photoshop®). All raster images that have a lower resolution than 300 dpi (dots per inch) often look pixelated. Please make sure all images are at least 300 dpi. An image that is 72 dpi may look fine on your screen but will not print well.

Color

Make artwork CMYK color values. Digital printing uses 4-color process inks (cyan, magenta, yellow and black) to create full color graphics. Digital printing can only create close matches to PMS and spot colors. Although we cannot guarantee custom color matches for all colors, we can closely match a wide range of hues. You will need to provide either a solid coated Pantone® color, or a printed sample of a color, for us to match. Please specify color matching when placing your order and call it out when signing off on your proofs. If color matching is not specified, your files will be printed as they were built. Color matching can delay the printing process depending on how art files are constructed. Please note, unless your screen and printer are calibrated they are not a good representation of the art when printed.

Black Ink

We recommend any black areas in your artwork be 100% K (Black). Not “rich black” or “built black” as these can cause ink chipping in the seal areas.

Format

Send all files as a PDF to avoid problems when converting. Please note the software that generated the art and send both the original and a PDF format of the art. This gives us the best opportunity to assist you with your project if changes need to be made. The PDF format will convert your art file to the format used for printing. Please review the PDF file once converted to make sure all effects look the way you want them printed.

*Want to learn more about how digital printing can protect your brand from anticounterfeiting? Download our Brand Protection Guide today.

When creating artwork for pouches that include clear windows or metallic finishes, it’s important to add a white ink layer in your file.

White ink acts as a base, blocking areas where you don’t want transparency or metallic shine to show through. Without it, colors may appear muted, or areas intended to be opaque may print translucent.

Be sure to set up your white layer as a separate spot color in your design file so our team can accurately apply it during printing.

What if I don’t see the quantity or size I need?

Contact us and we can send you a custom quote.

What is a gusset and what types are offered?

Simply, the gusset is the expandable portion at the bottom of the pouch. We offer a traditional K style gusset.

How safe is my food product in your pouch?

Very! Our pouches are manufactured with FDA compliant materials in a SQF certified facility. Pouch materials are safe for direct food contact.

How are the pouches shipped?

Our pouches are sent open at the top and are ready for filling. If you are hand-filling you will need to seal with a heat-sealing device. Watch this video showing you how to seal a stand up pouch with a band sealer.

What is a double cut or infinity edge?

When we form and seal your pouches there are instances where color from the previous pouch can bleed over. This can cause a very thin line of color to show up on the side of your pouch. We can trim that off to give you a consistent look. Requesting a double cut adds to cost, and usually isn't required with most pouch orders. Ask one of our packaging specialists if it makes sense for your project.

What is your turn time?

15 business days after proof approval.

How will my graphics be printed?

All art files will be produced digitally on a HP Indigo press. We can offer an extended color gammut to hit a vast majority of PMS colors.

Will I see a proof before printing?

Yes. During the order process, a PDF proof of your uploaded artwork will be available for approval. Printed press proofs are available for an additional fee.

Note: This will add at least 3-5 working days to your order and will be a flat proof - not formed or sealed.

Why are there three material types offered?

Each of the material compositions offer high barrier to moisture and oxygen which is meant to keep the product fresh. The metallic pouch offers the highest barrier properties. The clear material provides the opportunity to see the product within.

Are any of our pouches recyclable?

At this time we do not have any recyclable materials. Note: PCR (Post Consumer Recycled) materials will be available soon.

How To Order Mulitple SKU's.

Simply upload each design with its quantity — our cart will automatically calculate the best total cost for you.

- File prep for first file included. Additional files $75 each (e.g., 3 SKUs = $150).

- To qualify, all selected SKUs must share identical attributes (e.g., Size, Hang Hole, Zipper, etc.).

Pouch Size Calculator

Need help determining the right stand-up pouch size for your product? Use our Pouch Size Calculator to estimate the dimensions that fit your packaging needs.

*All sizes are approximate. Be sure to request samples to verify before production.

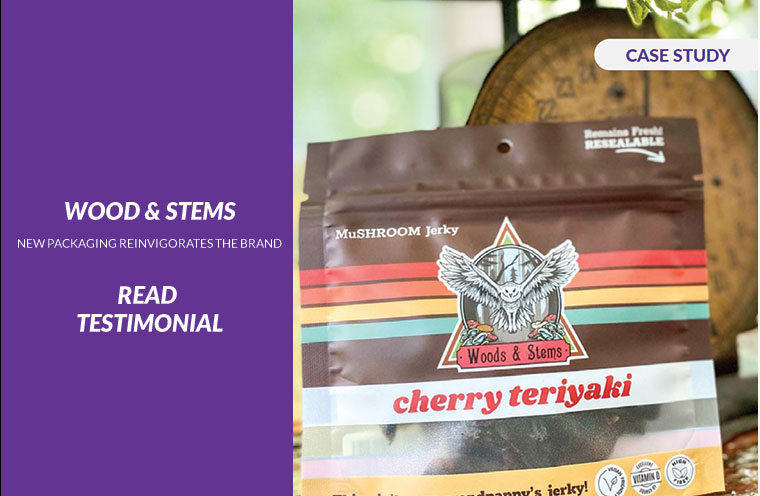

See Why Customers Love The Pouch House!

From small startups to large brands, businesses trust The Pouch House for high-quality, custom stand-up pouches that bring their packaging vision to life. Whether you need eye-catching designs, durable materials, or expert guidance, we’re here to help every step of the way. Don’t just take our word for it—see what our customers have to say about their experience working with us!

[Read Their Stories Below →]