Sustainble Packaging Is Here To Stay.

Consumer containers face a unique problem:

What is the end-of-life cycle for packages and what can be done to make them more Earth-friendly?

This is not a new topic of conversation. As this classic publication from 1971 demonstrates, the U.S. Environmental Protection Agency (EPA) and other organizations have been debating the re-use and disposal of consumer containers for decades.

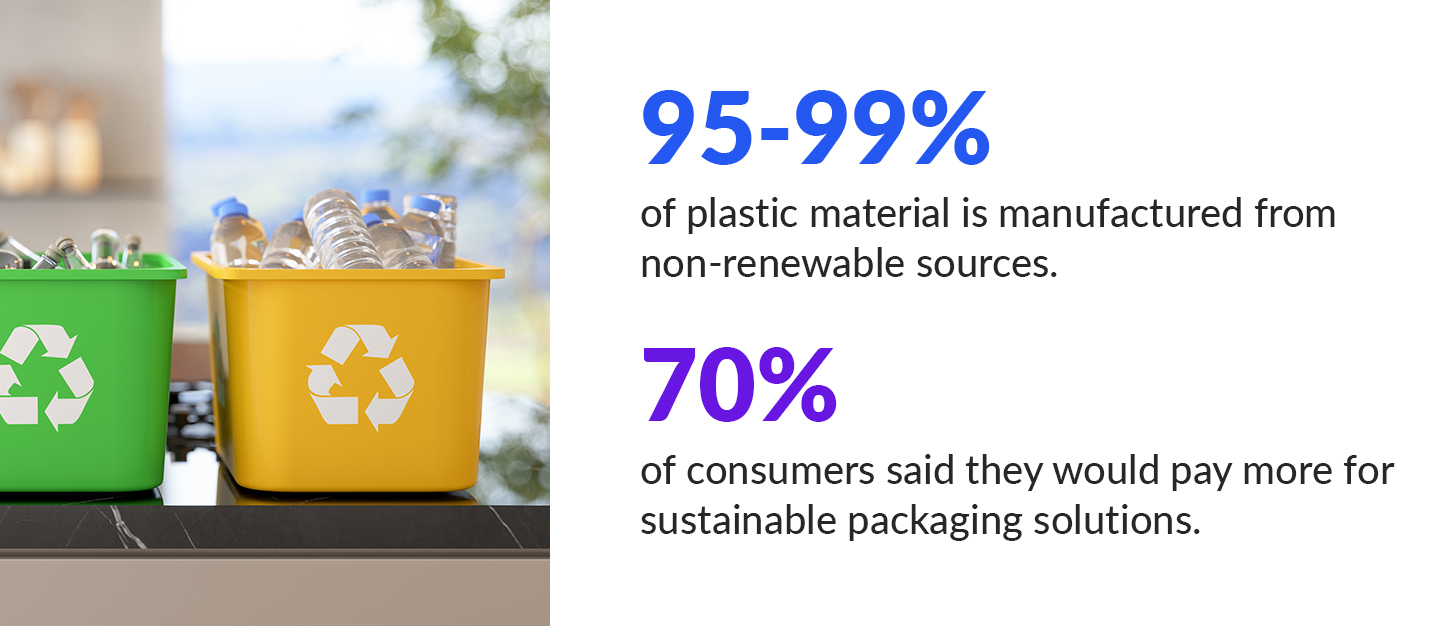

Alas, the more things change, the more they stay the same. Even half a century later, many packages are still made of non-recyclable materials — materials that often end up in landfills and harm the environment. In fact, according to an article in Science Direct, approximately 95-99% of plastic material is manufactured from non-renewable sources.

Now for the Good News

As discouraging as this many sound, there are a number of positive trends to note. Many businesses are now committed to developing smart, sustainable packaging that supports our home planet in a meaningful way. A 2020 study through McKinsey & Company showed that more than half of U.S. consumers are highly concerned about the environmental impact of packaging. Furthermore, they learned that up to 70% of consumers said they would pay more for sustainable packaging solutions.

For any sustainable packaging supplier, this is fantastic news. Flexible packaging, in particular, is a smart choice in designing consumer containers that are recyclable, compostable, or smaller in size (or perhaps even all three). Your choice of materials and the package design hold the key to making a package environmentally friendly.

3 Ways to Package Smartly

#1: Use Less Material

It sounds deceptively simple but transitioning products from larger containers to smaller ones can drastically cut down on the volume of materials used while still conserving their function. You can also do this by eliminating waste during the manufacturing and distribution stages.

- Work with your printer or package vendor to develop a container that is optimized to their processes and eliminates waste from the production process. For example, by reducing the package size slightly, you may be able to print two across instead of one across and thereby double your throughput.

- Consider marketing your product as a “just add water” concentrate and encourage consumers to refill a reusable container instead of providing a new container for each use.

- Look for ways to eliminate rigid packaging. One truck can carry millions of flexible packages compared to the multiple semi-trucks needed to deliver the same quantity of rigid containers.

#2: Reduce, Reuse, Recycle

This simple, widely-known phrase is a formula that businesses across all industries are adopting. The goal is to keep materials in use as long as possible without sacrificing quality. In order to properly choose which packaging materials are best, the first step is recognizing which materials can be safely recycled. For example:

- Polyethylene terephthalate (PET) bags can often be recycled in the drop boxes seen at the front of grocery stores.

- Aluminum, cans and paperboard are all recyclable in single-stream mixed recycling programs.

- Clear PET containers can also be recycled in mixed curbside collection bins.

To learn more about consumer container recycling, explore these resources:

- NexTrex has a store drop-off program for plastic bags and films.

- Plastics for Change explains which plastics can be recycled.

- How2Recycle® explains how to decode Resin Identification Codes and more.

#3: Compost (Carefully)

Composting uses organic, biodegradable materials that are meant to decompose back into the earth. While some compostable material for packaging exists today with more developments on the horizon, suppliers ought to carefully determine fit-for-use. While there are benefits to composting, some obstacles still remain:

- Compostable materials can have a reduced shelf life and be susceptible to moisture.

- Compostable materials can be less “robust” than other alternatives.

- Many consumers don’t know the difference between home composting and industrial composting.

No matter how suppliers choose to utilize flexible packaging, one thing is certain: sustainable packaging has a bright future. Ecoplast Ltd estimates that the flexible packaging market will jump in value from $182 billion to $325 billion by the year 2030. At the very least, using sustainable packaging will ease consumers’ consciences and help conserve the planet. For the packaging industry, that’s always a win.

We are excited to announce that The Pouch House now offers multiple sustainable packaging solutions, whether it is compostable or recyclable. We look forward to working with you to create the perfect sustainable solution for your brand and product. Reach out to customerservice@thepouchhouse.com to learn more!

The Pouch House: Flexible Packaging Made Simple

The Pouch House, a Taylor Corporation company, manufactures custom-printed flexible packaging products for customers across a range of industries. Companies engaged in snack food packaging rely on our Safe Quality Food (SQF) certification to ensure they are delivering safe food products to the marketplace. Brand managers appreciate our G7® Master Printer certification and the way we reproduce their signature colors with unwavering accuracy. And, procurement professionals appreciate our “six sizes, one solution” approach to flexible packaging that makes the ordering of custom lay flat and stand up pouches a breeze.

Make sure you know what your options are in the consumer container marketplace. Contact The Pouch House to learn more about our cost-effective flexible packaging products.

Leave your comment